Free shipping on orders over $99

Free shipping on orders over $99

Shop The Range

Do engraved vitals compromise the integrity of an AR500 steel target?

March 10, 2018

Short Answer: No

We've got a new line of absolutely amazing targets that we'll be releasing shortly that feature some waterjet engraving. This is uncharted territory for us so we wanted to make sure that we weren't going to have any issues with cracking at the engraving marks. One of the challenges we run into with testing is the fact that it's difficult to simulate the long term stresses seen my years of repeated use in a timeframe feasible with releasing new quality products in a timely manner...

Enter... the Barrett 82A1 .50 BMG! This is what I like to call a win/win/win.

Win 1: We get test results from targets showing how our targets will perform under conditions that far exceed what they should see in the field.

Win 2: We get to be sure that our customers are spending their hard earned dollars on products that we can be proud to have our name on for many years to come.

Win 3: Last but most certainly not least... I get to shoot a damn Barrett .50 cal! I mean, how sweet is that! (A big thank you to my brother for lending it to me and for donating all of the ammo of course!)

In a nut shell, how we tested our new engravings was as follows...

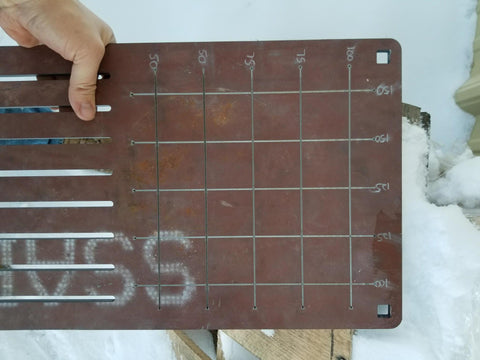

Step 1: We cut a test target with a grid of engravings at varying depths.

Step 2: We had the test plate powdercoated so we could see how defined each mark would be with the target in it's final form. We decided that the second to slowest travel rate was where we wanted to be.

Step 3: Using a waterjet we engraved a circle with cross hairs on the center of a 3/8" AR500 square gong measuring 8" in diameter. We wanted to hit it as hard as we could on the engraving marks to see if they would yield or sheer or simply show signs of fracturing. Now off to the range

Step 4: I set the target up at approximately 240 yards. This is far too close for this thickness of a target (should be out at 800-900 yards). I put a few rounds on target at this range. This particular rifle hasn't seen much use in the past several years and the ammo he gave me wasn't exactly cooperating, but I did get some good information.

240 Yard Results: Although I didn't get any dead center hits I did get near or on the engravings in a couple spots. The denting wasn't as bad as I thought it would be but there were dents that could be felt on the back of the target so there was a fair amount of energy imparted on the target. Ultimately there were no signs of cracking or fracturing on the target.

Time to move a little closer...

Step 5: I moved up to 50 yards! My field was full of snow that I didn't feel like laying in so I went to my favorite shooting position... prone in the back of my 99 Suburban with my rifle resting on the tailgate. I swear this vehicle was made to shoot from! The only reason I didn't use it to shoot from at 240 was because I was slightly concerned that the incredible muzzle blast from this beast would blow my tail lights to tail light heaven. I said a quick prayer that I wouldn't spend the afternoon fixing my vehicle and decided to go for it!

50 Yard Results: Even at 50 yards I didn't get a bullseye. There's got to be an issue with the ammo or perhaps the scope is loose. At any rate, I wasn't going to fix it there so I continued on. I did however get more hits at different points on the engraving and one dead center on one of the marks. Again, there was significant denting (although again not as severe as I expected) and some surface deformation but absolutely no signs of cracking or fracturing.

Final Thoughts: Taking a SWAG (Scientific Wild Ass Guess) at it, I believe that the way a waterjet cuts with not only high pressure water but also an abrasive, creates engravings that are relatively smooth. Any sharp points or jaggedness can create a point where stresses concentrate and can cause a crack to form (this is why there are no sharp corners on any of our targets, everything is radiused). Having smooth rounded edges allows that stress to be distributed evenly resulting in a target that doesn't crack or fracture. At the end of the day, the test target handled it like a champ and I'm confident to move forward with our new line of AR500 steel targets the likes of which the world has never seen!